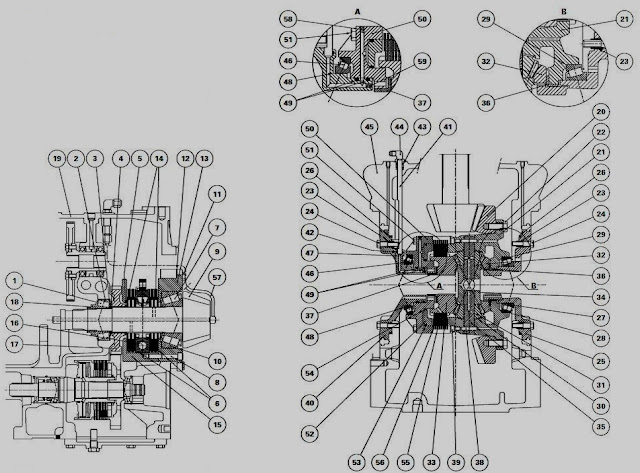

Removing and refitting the planetary gears and sun gears and disassembling and reassembling the crownwheel

Remove the differential unit assembly. Remove the locking system.

Removal

Remove the left-hand sun gear (33). To remove the half shafts (35), it is necessary to disassemble the crownwheel. Remove bolts (39).

Take out pins (38) from unit (21). Push on a half shaft in the direction of the arrow to drive out the opposite half shaft. Repeat the operation for the remaining half shafts. Recover the spherical washers (30). Remove the planetary gears (31). Remove the differential yoke and the right-hand sun gear (32). If necessary, drive cup (28) off the unit (21) and recover the shim(s) (29).

Disassembling the crownwheel

The replacement of the crownwheel automatically requires replacement of the drive pinion. Both parts bear the same number and they must always be fitted as pairs.

Remove bolts (22).

Refitting the crownwheel

- During repairs, use the bolts referenced in the spare parts catalogue.

Clean the mating faces of the new crownwheel (20) and unit (21) as well as bolts (22).

Screw two diametrically opposed guide studs into the tapped holes of the crownwheel. Assemble the crownwheel on the unit. Smear the first few threads of the bolts with Loctite 270 and screw them into the crownwheel. Remove the guide studs. Tighten and lock the nuts at a torque of 240 - 320 Nm.

Refitting planetary gears and sun gears

If necessary, place shim(s) (29) and insert cup (28) in unit (21).

- If replacement of the friction bushes (36) (37) is necessary, insert the new bushes lightly smeared with Loctite 638 using a suitable fixture.

- Check after insertion that the lubricating ports have not been blocked by Loctite.

Refit the right-hand sun gear (32) in the friction bush (36). Refit the differential yoke (34) as shown in the overall view. Check that the central channels and radial drilled passages in the half shafts (35) are not obstructed.

Assemble planetary gears (31), friction washers (30) and the half shafts, with the holes turned towards bolt (39) as shown in the overall view.

Position the shafts. Fit and tighten bolts (39) lightly smeared with Loctite 270 and tighten them to a torque of 25 - 35 Nm.

Manually check the rotation of the planetary gears and the right-hand sun gear (32). Refit the crownwheel. Refit the intermediate plates, discs and cover. Refit the differential unit assembly and the brake pistons. Fit and adjust the forward speed sensor. Refit the transfer tube (41) and union (44). Finish the refitting of the different assemblies.

Adjusting and checking the multidisc

The backlash between the crownwheel and drive pinion ensures reliability of the bevel gear and the correct operation of the assembly. This backlash must be checked after:

- adjusting the bevel gear distance

- shimming the differential unit.

Disassembly

Using an appropriate extractor, remove cup (28).

The thickness of the shim(s) "E" required to obtain the correct backlash is calculated as follows: E = Dc + 0.10 mm where:

E : thickness of shim(s) (29) to be fitted

Dc : crownwheel offset

- The Dc (example shown: -0.10) engraved on the external diameter of the crownwheel after the pairing number and letter (31 A) may range between 0 and -0.60 mm. When calculating �E� do not take the negative sign preceding the Dc into consideration. Place the previously selected shim(s) in the bore of the unit (21). Insert bearing cup (28) and check that it is in contact with the shims. Refit and shim the differential unit.

Checks

- Couple and temporarily fix the intermediate housing to the centre housing using several diametrically opposed bolts tightened to a torque of 540 � 680 Nm.

- With the PTO housing taken off, through the rear opening of the centre housing (45), place the index of a dial gauge half way across the length of a tooth of the crownwheel.

- Check that the multidisc is between 0.15 mm and 0.45 mm. Carry out this check at three points around the crownwheel.

- If the backlash is incorrect, the adjustment principle is to reduce or increase the thickness of shim(s) (29).

- In this case, select and fit a different thickness of shim(s). Carry out the shimming of the differential unit again in order to obtain the pre-loading of bearings (27) (28) and (46) (47).

- Check a second time the backlash between the drive pinion and the crownwheel.

When the final adjustment has been obtained, go on with the refitting operations.

Shimming the differential unit

If the centre housing (45), crownwheel, taper roller bearings and carriers (25) (40) have been replaced, carry out shimming of the differential unit. Check beforehand that the shim(s) (29) used for providing the multidisc are fitted between unit (21) and cup (28).

Shimming preparation

Place the differential assembly in the housing using sling ref. 3378116M1. Screw two diametrically opposed guide studs into the centre housing. Insert carrier (25) fitted with a new O�ring (26) using four bolts (24). Remove the guide studs. Complete the refitting of the other bolts and tighten to a torque of 100 - 130 Nm. Remove bearing cone (46) and shim(s) (48) from carrier (40).

Slide bearing cone (46) on tool, ref. 3378117M1, adapted for the hypoid differential unit with multidisc lock. Using two bolts, fix the tool onto the housing.

Tighten the centre bolt to 10 Nm. Turn the crownwheel several times to seat the cones correctly in the cups. Check the tightening torque of the centre bolt again. Dimension to be measured on the housing (45).

Using an appropriate depth gauge, measure dimension "B" at two opposed points (work out average of the two measurements) and determine dimension "C" between bearing cup (46) and the thrust face of the carrier (40) on the housing: C = B � 10 mm(10 mm is the thickness of tool, ref. 3378117M1). Dimension to be measured on carrier (40).

Measure dimension "Y" using an appropriate depth gauge and rule.

Calculate distance "E" between the thrust faces of bearing cup (46) and carrier (40): E = C � Y. Fill in space "E" with a thickness of shims (48).

In space "E", add additional shims between 0.05 mm and 0.15 mm, in order to obtain P2: P2 = 0.05 mm to 0.15 mm. Remove the tool and bearing cup (46).

0 comments:

Post a Comment