The tractors is equipped with an AG250 Full Powershift gearbox and have a wide intermediate housing in which the axial position of the drive pinion has been redesigned for the fitting of a hypoid bevel gear.

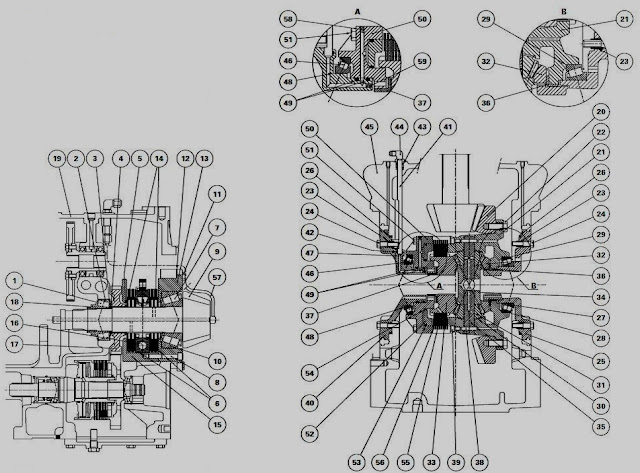

Parts list

(1) Bearing cone (2) Bearing cup (3) Shim(s) (4) Thrust washer (5) Circlip (6) Intermediate plates (handbrake) (7) Bearing cone (8) Bolt (9) Drive pinion (10) Bearing cup (11) Bolt (12) Shim(s) (13) Bearing carrier (14) Discs (15) Handbrake unit (16) Mechanism (17) 4 WD drive pinion (18) Nut

(19) Intermediate housing (20) Crownwheel (21) Unit (22) Bolts (23) Centring bushes (24) Bolts (25) Right-hand carrier (26) O�rings (27) Bearing cone (28) Bearing cup (29) Shim(s) (30) Spherical washer (31) Planetary gear (32) Right sun gear (33) Left sun gear (34) Differential yoke (35) Planetary gear half shafts (36) Shouldered bush (37) Shouldered bush (38) Needle bearings (39) Bolt (40) Left-hand carrier (41) Transfer tube (42) O�ring (43) O�ring (44) Union (45) Centre housing (46) Bearing cone (47) Bearing cup (48) Shim(s) (49) Seal rings (50) Cover (51) Bolt (52) Piston (53) O�ring (54) O�ring (55) Intermediate plates (differential lock) (56) Discs (57) Lubricating pipe (58) Rivet (59) Rivet

Construction

The bevel gear, moved in rotation by the gearbox output shaft, drives the rear axle. The helical drive pinion is supported by two taper roller bearings mounted in opposition. The bearing cone (7) is force fitted on the drive pinion, and cups (2) (10) are likewise force fitted into the intermediate housing (19) and bearing support (13). The bearing cone (1), mounted free on the drive pinion, allows to fit the shims (3) required for shimming. The crownwheel is fastened to the differential housing by bolts. The differential assembly rotates on two taper roller bearings supported by two lateral carriers centred by bushes (23) and fixed by bolts to the housing. The differential assembly is formed by two halves holding four planetary gears (31) and two sun gears (32) (33). The left-hand side sun gear also serves as the hub for the differential lock discs (56). The planetary gears turn on four half shafts (35) housed in the unit and the differential yoke (34). They are held in place by pins and bolts.

The lubrication of the planetary gears is carried out by axial and radial channels drilled in the half shafts. The sun gears, left-hand carrier (40), cover (50) and the differential yoke contain drilled lubrication channels allowing

transmission oil to reach bushes (36) (37), discs (56) and the differential lock system. The drive pinion, which bears the 4 WD drive pinion (17), is located in the intermediate housing. The adjustment of its position is carried out by shims (12) fitted between the bearing carrier (13) and the housing. The pre-loading of the bearings is obtained by shim(s) (3) fitted between the bearing cone (1) and the thrust washer (4). The preloading via shimming of the differential assembly is carried out via shim(s) (48) placed between bearing cone (46) and the left-hand carrier (40). Backlash of the drive pinion and the crownwheel is obtained by using shims (29) inserted between cup (28) and the differential half-housing (21).

Differential lock

The multidisc lock system comprises:

- a unit (21) housing the discs (56) and intermediate plates (55).

- a hub (33) integral via splines with the left-hand trumpet input sun gear.

- a cover (50) made up by piston assembly (52) and supported by taper roller bearings (46) (47).

The piston chamber lodged in the cover communicates with a channel in the left-hand carrier (40), allowing (17 bar) low pressure to act upon the piston. Two seal rings (49) ensure the oil tightness of the circuit.

Operation

Clutched position

When the differential lock solenoid valve is activated, the pressure flows through the channels in left-hand carrier (40) and cover (50) on unit (21) and enters piston chamber (52). The piston compresses the intermediate plates (55) and discs (56) integral respectively via stops and splines in lock unit (21) and hub (33). In this �clutched� position, the input sun gears of the righthand and left-hand trumpets turn at the same speeds.

Declutched position

When the pressure is cut, the piston returns, the discs and intermediate plates are no longer compressed and allow the sun gears and planetary gears to carry out their differential function.

Removing and refitting the carriers

Left-hand carrier

It is possible to carry out maintenance on carrier (40) and seal rings (49) of the differential lock by removing only the left-hand trumpet housing.

Removal

Remove the left-hand trumpet housing.

Take off union (44) and raise the transfer tube (41). Remove the brake piston.

Remove bolts (24) on from the left-hand carrier. Place two diametrically opposed guide studs "G" on the housing as shown in Figure, their ends pushing against cover (50) of the lock unit.

Extract the carrier by inserting two bolts "V" through the tapped holes; take it off and recover cone (46) and shim(s) (48). The guide studs "G" hold and centre the differential assembly in the housing. Do not unscrew the guide studs. This may throw off centre the assembly and damage the seal rings (49) during refitting of the carrier.

Refitting

Check for the presence of centring bush (23) on the housing, the shim(s) (48) and bearing cone (46). Check that the seal rings (49) are not damaged and that they turn normally in their grooves. After this check, remove the seal rings and coat them with miscible grease, so that they remain at the bottom of the groove during refitting of the carrier. Fit new O�rings (26) (42).

Slide the carrier onto the guide studs"G" and alternately and uniformly tighten the four bolts (24) to a torque of 100 - 130 Nm. Remove the guide studs. Fit and tighten the other bolts to the same torque. Position the transfer tube (41) in carrier (40). Screw in and position union (44). Refit the brake piston.

Check the oil tightness of seal (26) on carrier (40). Refit the left-hand trumpet housing.

Right-hand carrier

The access to the right-hand carrier (25) is similar to that of the left-hand carrier (40).

Removal

- Take out bolts (24) and place diametrically opposed guide studs "G" in the housing, their ends thrust against the half-housing (21).

- Extract the carrier by inserting two bolts "V" through the tapped holes and remove it.

Refitting

- Check for the presence of the centring pin (23) on the housing and O�ring (26).

- Tighten uniformly and alternately the four bolts (24) to a torque of 100 - 130 Nm. Remove the guide studs. Fit and tighten the other bolts to the same torque.

- Check the oil tightness of seal (26) on carrier (25).

0 comments:

Post a Comment