On tractors where one or more elements of the auxiliary spool valves are operated mechanically, take care to disconnect the link cable(s) without turning the main spool of the valve a half turn.

Preliminary operations

Place the lift arms in the low position.

Disconnect:

� on mechanically operated spool valves

- control cable (2), taking the above reminder into consideration;

� on Joystick or lever operated (Dual Control) spool valves

- solenoid valve (18), connector(s) C linked to the spool valve electrohydraulic unit(s), marking their position(s).

Removing the spool valves

The spool valve block assembly must be removed complete before working on it. Any operations carried out on the spool valves require scrupulous cleanliness. First correctly clean the spool valves (lift control and auxiliary) and the areas around them before removing them.

If necessary, remove all the spool valves one after the other and disconnect the hydraulic connections as they are removed.

Removing the lift control spool valve

Take off the supply and return pipes

Disconnect the connectors of the lifting and lowering solenoid valves. The brown connector is connected to the right-hand solenoid valve used to lower the lift control. Remove the spool valve assembly.

Remove lift control spool valve.

Removing the inlet block

In order to fit the auxiliary spool valves in horizontal position, it is necessary to remove the spool valve block assembly.

Loosen the P � R and LS unions, disconnect the hydraulic union and electrical connectors, and remove the spool valve block. Remove the inlet block.

Install the spool valves

Wipe clean the mating faces of the inlet block, the lift control spool valve, the auxiliary spool valves and the end plate. Check that each element is perfectly flat. Check the tightness of the studs on the inlet block.

Position the new seals (2) (3) (4) and (5) on each element of the distribution block (1).

Assemble the distribution block on the workbench by superposing the elements and following the assembly procedure.

Reinstall fit the complete block on the tractor.

Reconnect the hydraulic pipes and electrical connectors.

Reconnect:

� on mechanically operated spool valves

- the lifting and lowering solenoid valve connectors in accordance with marks made during removal,

- the control cable(s);

� on Joystick or lever operated (Dual Control) spool valves

- the lifting and lowering solenoid valve connectors in accordance with marks made during removal,

- the connector(s) linked to the electrohydraulic unit(s), according to marks made during removal,

- the solenoid valve located on the end plate.

Start the engine, place the lift control arms in the low position.

At each position, check the operation of:

- the hydraulic system.

- electronic system.

Check the oil tightness of the spool valves and hydraulic unions.

Assembly procedure

To obtain the correct assembly of seals (2) to (5), the reassembly of each spool valve must be carried out vertically on the workbench.

Assembly on the workbench

In this order, stack the input unit, an auxiliary spool valve, a support block, the lift control valve, an additional support block, and the auxiliary spool valves.

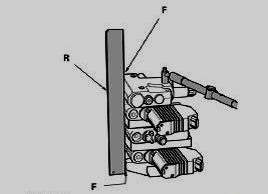

Place a steel ruler R thrust against face F of the distribution block so as to align the fixing points equally and correctly.

Tighten the nuts (1) to a torque of 30 - 33 Nm.

After the assembly of the spool valves, carry out the reassembly operations.

0 comments:

Post a Comment